Open and close at speeds up to 2m/s for enhanced efficiency.

Innovative insulation and design minimize energy loss.

Withstands wind pressures up to level 12 for safe operation.

Multiple options for easy remote and one-button operation.

Handles thousands of cycles daily with low maintenance needs.

· Opening speed 0.8m/s ~2m/s (adjustable)

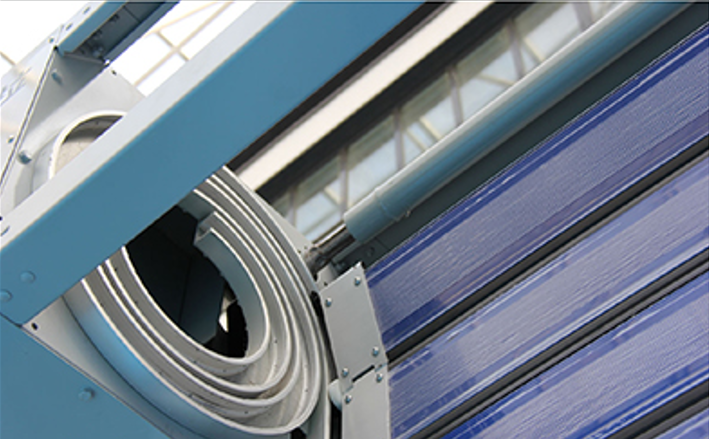

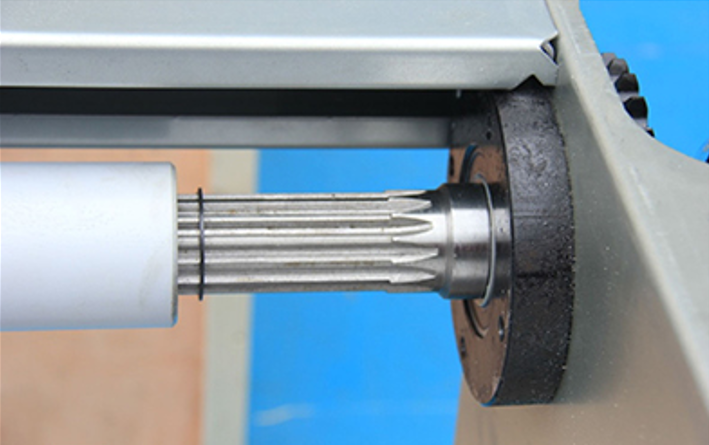

· Archimedean spiral principle, double-layer turbine structure, reduce resistance, reduce friction, and run more smoothly at high speed.

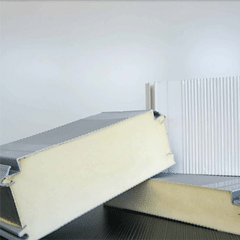

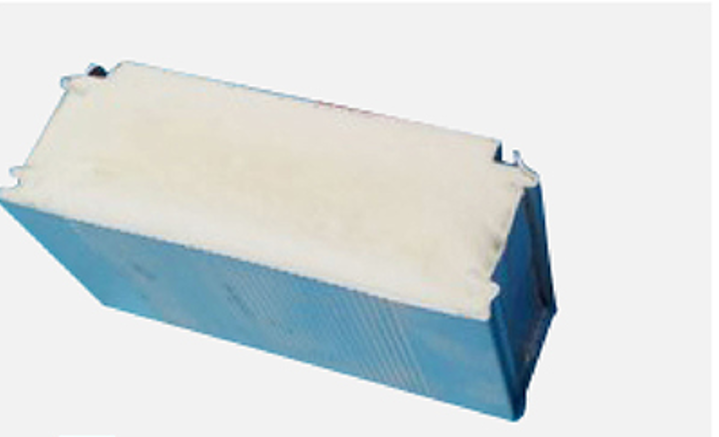

· The door panel adopts patented broken bridge design with good heat preservation effect, heat preservation: national standard level 3

· Resistant to 12 winds, wind resistance: national standard level 3

· Daily opening and closing times reach thousands of times

· Total trouble-free operation exceeds 1 million times

· Radar, geomagnetism, remote control, Bluetooth, APP, etc., a variety of intelligent opening methods are available

· One-button start, interlocking, linkage, customized on demand

| Speed | Up to 2.5m/s (98.43 inches/second) with servo drive. Maximum speed depends on door size. |

| Size | Minimum: 1000mm(3.28’DOW) x 1000mm(3.28’DOH) Maximum: 8000mm(26.25’ DOW) X 9000mm(29.53’DOH) |

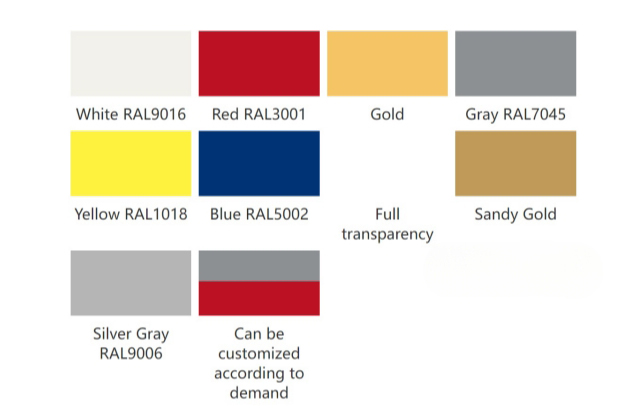

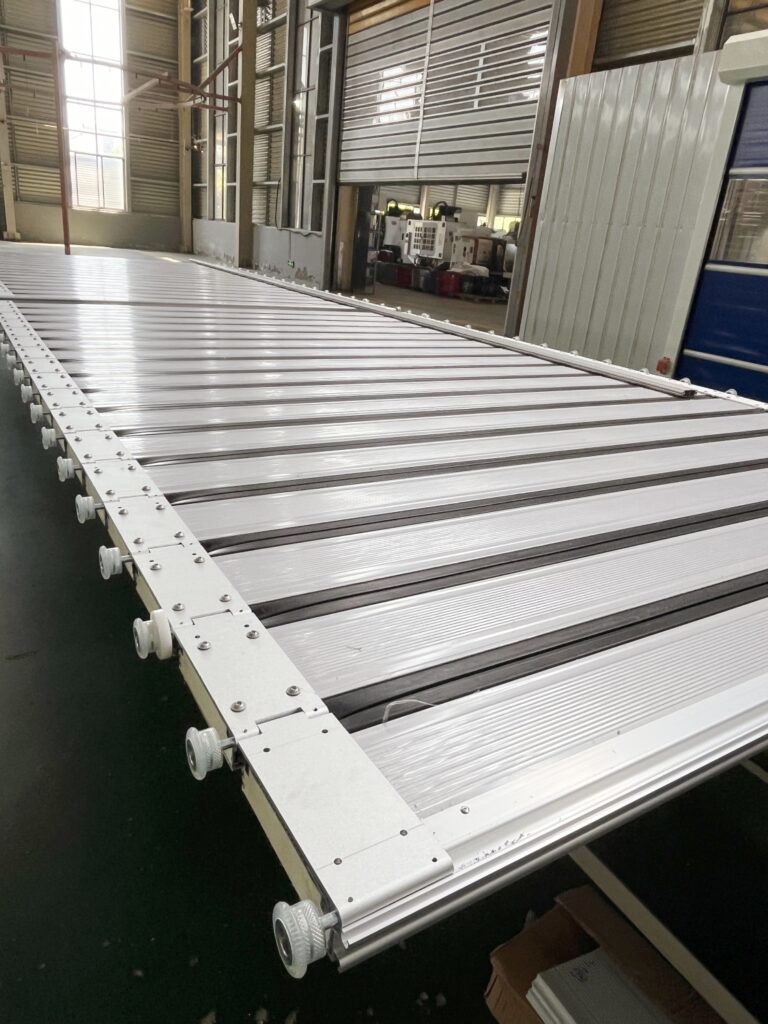

| Panel Material | 0.7mm(0.028”) thick is for aluminum plate foaming density is 45kg/m3(2.8lb/ft3) thickness is 43mm(1.69”) and 80mm(3.15”) the height is 220mm(8.66”) for single panel color: white(RAL9016); silver(RAL9006); grey(RAL7045); aluminum original color |

| Drive System | Using three kinds of servo-motor: 0.75KW, 1.5KW and 2.2KW. This depends on the door size. Each motor assembly is with gearbox and brake. Servo-drive control the running of motor. motor drive the panel through the transmission chain and drive shaft and lift chain. The tension spring will counterbalance the weight of panel. |

| Electrical Requirements | standard: 220V/1PH/50/60Hz(servo-motor) oversize door: 380V/3PH/50/60Hz(induction motor SEW with VFD) door sizes greater than 36m² (for 36mm thick panels) and 30m² (for 80mm thick panels) |

| Vision Options | The material is transparent PC with a thickness of 2mm. For 80mm thick panels the dimensions are 422mm (16.61 inches wide) x 168mm (6.61 inches high) For 43mm thick panels the dimensions are panel width through, 140mm high |

| Control Box | Servo-drive, metal enclosure size: 250mm (9.84”W) X 450mm(17.72”H) X 150mm(5.91”D) |

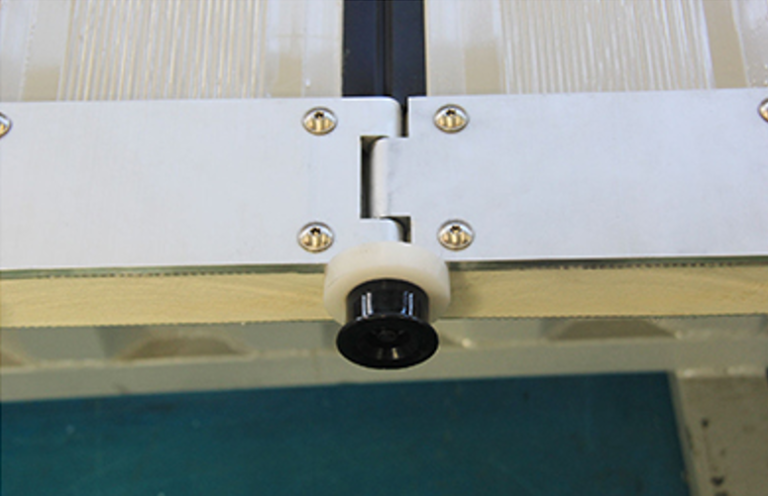

| Panel Retention | Guide rollers maintain panel tension over the entire length of the side frame. When the door width is less than or equal to 3M (9.84 ft.), the wind pressure is 32 M/S (3.5 KPA, 71.6 MPH). Larger doors will have wind pressures below this value. |

| Safety Features | low level: one pair of photoelectric sensors and wireless airbags high level: two pairs of photoelectric sensors and wireless airbags option: light curtain |

| Lift Style | Round Spiral, Oval Spiral |

| Warranty | 13 months after delivery low level: 70,000 cycles or 1 year high level: 150,000 cycles or 2 years |

» 1. Material Preparation and Selection

The process begins with the selection of high-quality materials, such as galvanized steel or aluminum, for the door’s structural components. These materials ensure durability, corrosion resistance, and long-term reliability.

» 2. Precision Cutting and Machining

Using CNC cutting technology, the door panels and structural components are precisely cut to the required dimensions. This ensures that each part meets the strict specifications needed for the smooth operation of the high-speed spiral mechanism. The key structural components, such as the spiral tracks, are machined with an accuracy of up to 10 microns to allow seamless door movement.

» 3. Assembly of the Spiral Track

The spiral track, made from precision-machined aluminum or steel, is assembled. This double spiral design enables the door panels to roll up efficiently without causing wear or requiring frequent maintenance. The automated spline shaft system is integrated into this step, which is designed to be maintenance-free and highly durable.

» 4. Door Panel Production

The individual door panels are manufactured and assembled. These panels are often made from materials like insulated steel or aluminum, providing both thermal insulation and structural integrity. The panels are coated with protective layers to enhance weather resistance and reduce noise.

» 5. Final Assembly and Testing

After assembling the spiral tracks and door panels, the high-speed door system is tested for smoothness and efficiency. The door is operated multiple times at its rated speed to ensure it meets performance standards, including wind load resistance, airtightness, and operational speed.

» 6. Quality Inspection

A final quality control step is performed to ensure all components meet the required standards. This includes checking the thickness of the materials, the integrity of the spiral tracks, and the overall operation of the door system.

Frictionless operation, capable of more than a million cycles.

The thermal break provides insulation and helps save energy.

Maintenance-free, durable, and easy to use.

Made from high-strength aluminum alloy material, surface anodized, rust-resistant, and more durable.

Dual protection for enhanced safety and security.

Ensures effective sealing at various points.

Convenient and reliable operation.

Allows for quick manual disengagement during power outages.

Experience Unmatched Speed and Precision for Your Facility

NHentrance Co., Ltd. specializes in high-performance industrial doors, such as high speed spiral doors, high speed PVC doors and sectional doors. With over two decades of expertise, NHentrance operates advanced production facilities in Wuxi and Dongtai, ensuring large-scale output and meeting the demands of global markets.

Our products adhere to stringent European industry standards and have earned prestigious certifications, including the EU CE mark, international SGS, and ISO9001 Quality Management System certification. NHentrance’s commitment to quality and innovation has exported its products to over 30 countries and regions, including the European Union, the United States, Canada, France, Australia, Dubai, India, etc.

Serving industries such as manufacturing, logistics, electronics, and food processing, NHentrance delivers tailored solutions designed to meet the diverse needs of its international clients. With a dedicated R&D team, we prioritize advanced engineering, durability, and operational efficiency.

NHentrance’s reputation for exceptional quality, competitive pricing, and comprehensive customer support makes us a trusted partner for businesses worldwide, offering reliable, innovative, and certified solutions for industrial applications.

Our team has over 20 years of experience in the door industry. Deeply understanding of door construction and performance.

We are committed to providing our customers with high-quality products at competitive prices.

Strictly adhering to international quality standards and obtaining lSO certification to ensure product reliability.

Offering professional pre-sale consultation and post-sale support to ensure customer satisfaction and loyalty.

Designed for efficient on-site installation, our modular spiral door kits offer fast delivery within one week, minimizing downtime and simplifying logistics.

A high-speed spiral door is an advanced industrial door engineered for rapid operation, offering efficient, secure, and reliable access control. These doors are ideal for facilities where fast movement of goods is essential, such as logistics centers, manufacturing plants, and cold storage environments.

NHentrance high-speed spiral doors can achieve speeds up to 2.5 m/s (98.43 inches/second), depending on door dimensions and custom specifications. This helps accelerate operations in time-sensitive industries.

The door panels are available in insulated aluminum or PU-filled panels, ensuring both thermal efficiency and durability. Frames are manufactured using high-quality materials like Shougang galvanized steel or Shanxi aluminum, known for their strength and corrosion resistance.

The spiral design allows the door slats to retract smoothly into a compact, spiral track. This unique feature significantly reduces wear on moving parts, ensures quieter operation, and provides superior thermal insulation compared to high-speed PVC doors.

NHentrance offers custom door sizes to meet your specific requirements. Typical dimensions range from 1000mm x 1000mm to 8000mm x 9000mm, allowing installation in both compact and large-scale facilities.

NHentrance high-speed spiral doors feature low-maintenance components, such as an automatic adjustable telescopic spline shaft that is wear-resistant and maintenance-free. Routine inspections and lubrication of critical components are recommended to ensure long-term performance.

Yes, NHentrance offers comprehensive customization options, including size, color, insulation properties, and control systems, allowing the door to meet the specific needs of your facility.

Discover the perfect high-speed door solution for your business. Contact us now for pricing and details!